SU 134B Coater

This equipment is used for pre-printing, glazing after printing, and longitudinal blanking coating on the metal sheet packaging surface of food cans, beverage cans, aerosol cans, metal toys, daily-use chemical cans, lids, and boxes. It is an essential supporting equipment for sheet metal offset printing.

The transmission gear of this machine is a helical gear, and the transmission is stable.

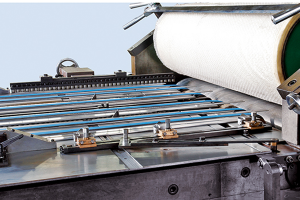

It adopts a scraper for paint, a scraper for solvent, and a double scraper device with a scraping function.

The scraper is fixed by plug-in type, which is very convenient to assemble and disassemble.

The idler roller is made of nickel-chromium-molybdenum chilled cast iron or sprayed with WC, which has a long service life and high surface precision.

The machine is simple in structure, easy to operate and maintain.

It can ensure the vertical space of the metal sheet, and is equipped with a side gauge device with movable side gauges and multi-roller side gauges.

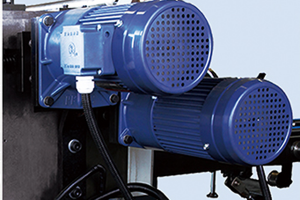

The oil transfer roller is driven by a separate frequency conversion motor.

The main technical parameters:

| Applicable to the largest sheet metal specification | 1143×930(mm) |

| Applicable minimum sheet metal specification | 712×508(mm) |

| Sheet metal thickness | 0.16~0.5(mm) |

| Brief specification of idler roller | φ254×1180(mm) |

| Rubber roller size | φ356×1155(mm) |

| Oil roller size | φ203.22×1150(mm) |

| Down transfer roller size | φ203.22×1150(mm) |

| production capacity | 4800(p/h) |

| machine weight | 3100(kg) |